Kaolinite is an industrial mineral belonging to the group of aluminosilicates. The term kaolin is used to describe a group of relatively common clay minerals, primarily kaolinite and is produced by the chemical weathering of aluminium silicate minerals like feldspar. It is a soft, earthy, usually white, mineral (dioctahedral phyllosilicate clay).

Kaolin’s commercial attributes primarily revolve around being chemically inert over a relatively wide pH range, brightness, film strength, whiteness, opacity, gloss, viscosity, low heat and low electrical conductivity, which leads to a diversified range of industrial applications, some of which include:

- Paper coating – to hide the pulp strands

- Ceramics – high fusion temperature and white burning characteristics makes it particularly suitable for the manufacture of whiteware (china), porcelain

- Paints – as an extender and flattening agent

- Rubber – filling rubber to improve its mechanical strength and resistance to abrasion

- Coil Coating

- Colour Pencils

- Plastics

- Cement and Fibreglass

Kaolin is also emerging as a cost effective and environmentally friendly source of Alumina (Al) and can be applied as feedstock in the production of High Purity Alumina (HPA) and commercially versatile manufactured zeolites.

About the Toondoon Project

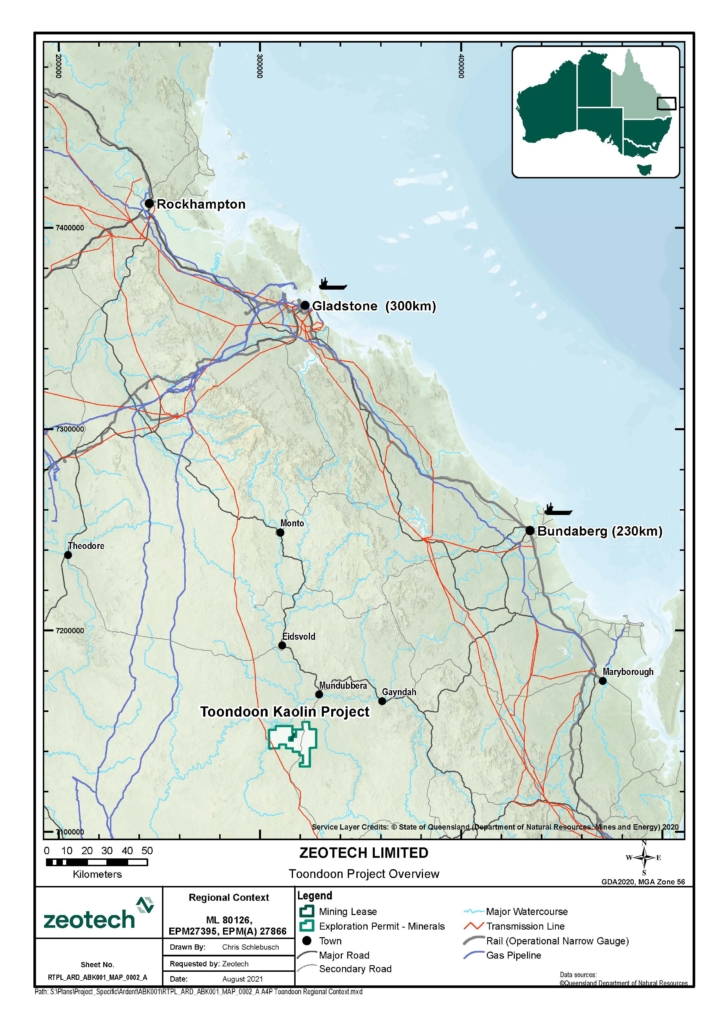

The Toondoon project revolves around an ‘approve mining lease’ ML 80016 and EPM’s 27395 and 27866. The project hosts one of the highest-grade raw ore kaolin deposits in Australia. The project spans over 28,000 hectares and is located approximately 20 kilometres south of Munduberra, Queensland. The mine site is situated approximately 230km from the Port of Bundaberg and 300km from the Port of Gladstone and has access to major highways across sealed roads.

Geology:

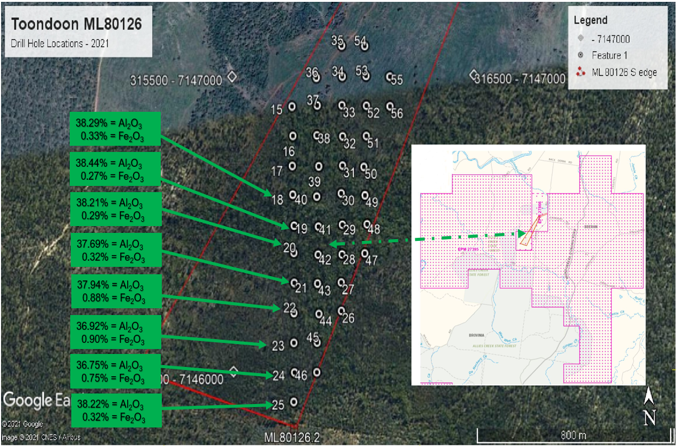

Recent resource estimation test work at the Toondoon Mining Lease, ML 80126, has delivered an Indicated JORC 2012 Resource of:

White Kaolin Clay – 5.07Mt @ 37% Al2O3, 0.9% Fe2O3, 46.3% SiO2, Alumina/Silica Ratio of 0.80.

The potential exists to expand the high-grade kaolin resource, which remains open in all directions.

Industrial kaolin attributes:

Testing of Toondoon high-grade kaolin indicates up to 76% ISO brightness on raw ore samples, increasing to 84.5% post elutriation. JORC confirms indicated resource of 37% Al2O3, over five million tonnes – providing Zeotech with access to some of the highest-grade raw ore kaolin in Australia.

The high alumina content will allow the ore to be highly suitable to a number of sectors including the white cement industry, refractories, and fibreglass manufacturing. The ISO brightness enables end-users to process DSO for paper, packaging, and coating markets.

Toondoon project highlights include:

• Resource remains open in all directions

• Large scale mineralised system from surface

• High Grade alumina and low iron content assay results

• Low cost operation – straight forward open cut mining

• Little to no overburden

• Low impurities

Other kaolin projects

Zeotech also holds the Abercorn Project, which has a consistent grade of kaolin mineralisation.